Subsea burial

Enabling successful cable and pipe burial.

As the growth of offshore wind accelerates, and wind farms are installed in an increasingly diverse range of locations, the need to maximise productivity and protect the product has never been higher.

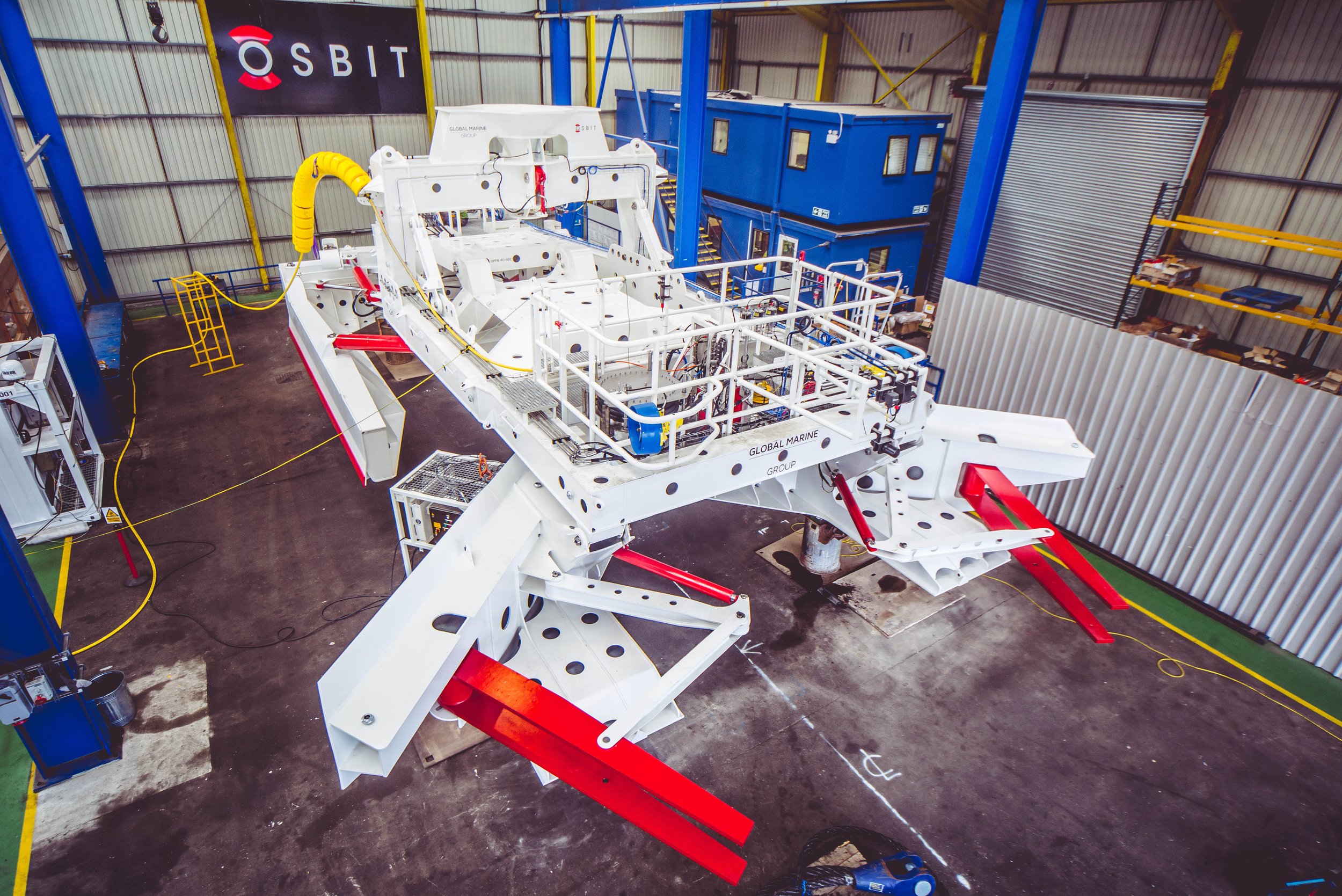

We have decades of experience in developing and modifying subsea trenching vehicles, to enable successful campaigns.

To date, we’ve developed multiple field-proven subsea trenching systems, and completed a variety of upgrade and repurposing projects on existing assets.

What we do

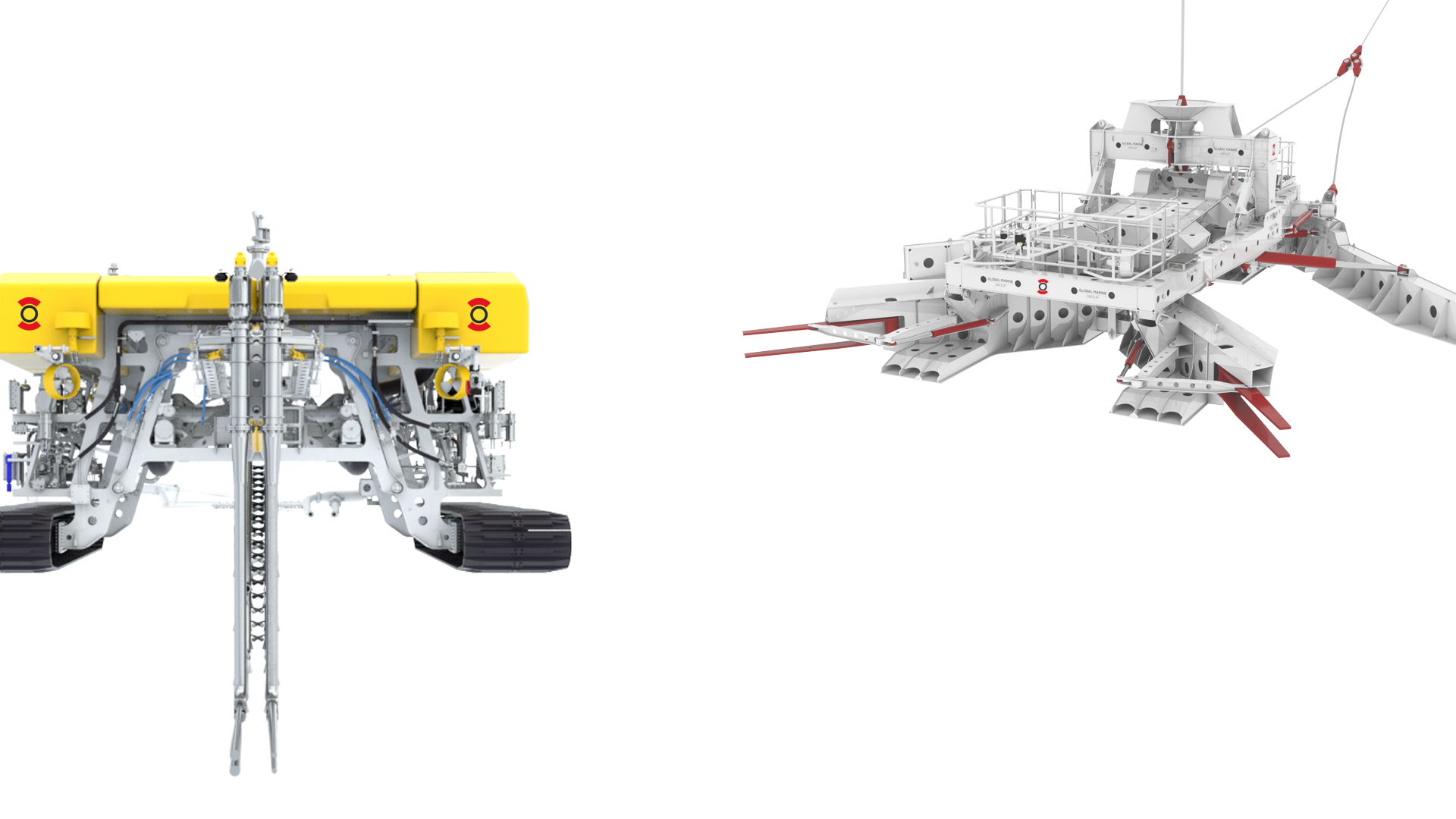

We design, build, support, and upgrade a diverse range of subsea burial systems to bury subsea cables, pipelines, and umbilicals.

These include mechanical jetting and cutting trenchers, pipeline and cable ploughs, controlled flow excavators, jetting tractors and sleds.

Our skills range from turnkey supply of subsea trenching solutions, to modifying existing systems, integrating new control systems, and supplying sub-systems such as cutting wheels, jetting swords, and shares.

How we can help

-

We deliver tailored studies and concept design to inform project decision-making, from simple feasibility assessments through to complex FEED.

-

We develop and deliver cutting edge systems to drive our customers’ operations forward.

-

We provide multi-discipline commissioning support, as well as offshore operational and maintenance teams.

-

We offer tailored spares packages, desktop studies, and remote engineering support, as required.

-

We optimise, repurpose and diversify asset capabilities, as well as inspecting, surveying, and carrying out planned maintenance.

-

Our Tailwind software package can be integrated on new and existing assets, streamlining knowledge management, and providing performance insight and inventory management.

Key benefits delivered

Dive deeper into our track record…

Sharing knowledge to drive industry progress

We’re working with developers, vessel owners, and equipment operators to share technical trenching knowledge across the offshore wind supply chain.

Our Osbit Insight offering is increasing project success and supporting developers in making agile, lower-risk decisions when it comes to offshore operations and technology selection.

Offering the best of technology…

Our approach combines innovation with already proven, modular aspects of Osbit technology. This enables us to increase capability and lower lead-time, all while decreasing each project’s risk profile.

Our capabilities cover the entire equipment life-cycle; as well as full design & build equipment supply, we offer tailored packages based around any segment or combination of our core offering components.

Let’s talk subsea burial…

If you have an equipment requirement, or would simply like to learn more about Osbit’s capabilities, then please get in touch.

Our other technology