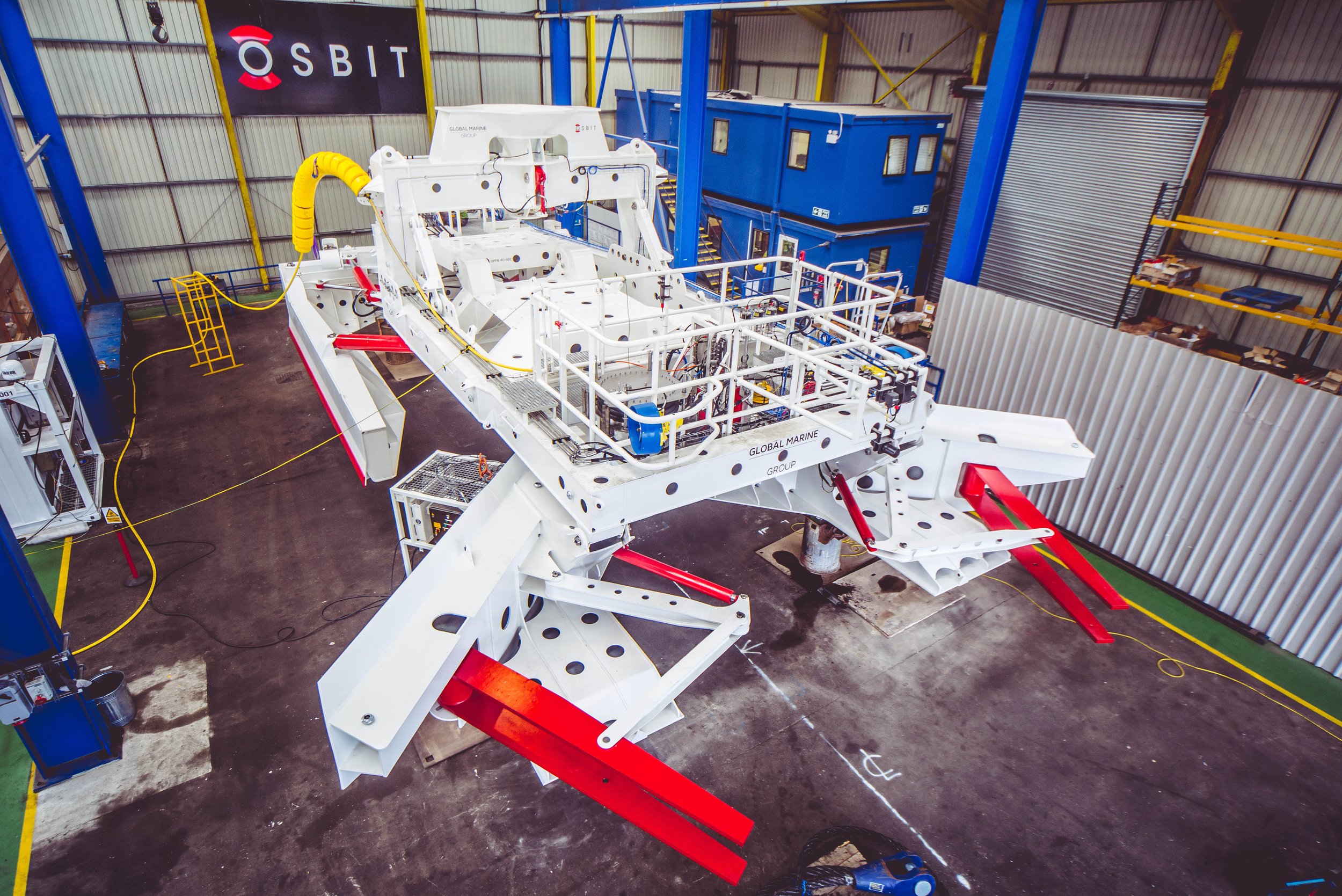

Pre-lay subsea plough

Developing a collaborative concept to help our customer win their contract, developing world-first technical capability, and meeting the demands of an accelerated delivery programme.

Driving industry progress through collaboration.

Global Marine Group reached out to Osbit in the early stages of a project bidding process with a major Swedish developer, with the understanding that our input could support their bid.

By working together from early on in their bid process and including Global Marine Group’s client in the discussions, our team was able to understand the problem, share our expertise to support their decision-making, and develop an innovative concept to solve their specific operational challenges.

This plough concept directly supported Global Marine Group in securing their contract to conduct inter-array cable installation on the 605MW Kriegers Flak offshore wind farm in Denmark. Osbit was then employed to supply the system.

Developing world-first ploughing capability.

Global Marine Group and its first client for the new plough, were seeking to deliver a burial asset to help reduce the cost of offshore wind installation. They sought to achieve this by minimising project risks and utilising a different technique for the burial of cables in a dense boulder field.

To achieve this, our patented design enabled world-first integration of simultaneous cable route clearance and pre-trenching in one plough system.

-

The key innovations of the pre-lay plough include its ability to conduct boulder clearing and trenching operations simultaneously within a single pass, enabling Global Marine Group to significantly reduce construction time for wind farm installation.

The vehicle is reconfigurable, and can also complete backfill operations using the segregated spoil heaps that are prepared during trenching operations. The plough’s market-leading, comprehensive control and surveillance system ensures accurate trenching.

-

The plough offers unrivalled single pass capability, which enables boulder clearance and pre-trenching up to 1.7m in a single run, leaving a boulder cleared swathe and a ‘backfill-ready’ open trench with segregated spoil. The plough is also fully subsea adjustable and features an extensive surveillance suite for accurate and effective trenching.

The plough can be reconfigured into backfill mode, which uses the same control and surveillance suite to monitor the cable and trench profile, enabling reliable backfilling whilst ensuring the safety of the cable at all times. Our innovative forward skid arrangement and surveillance equipment provide market-leading levels of cable integrity assurance.

-

The plough is also supported by our leading control technology, which consists of an open source modular system incorporating asset monitoring, packaged in an ergonomic control cabin.

Meeting an accelerated delivery schedule.

Time is money, in the offshore world. Another key aspect of this project was the need to meet an accelerated and demanding project delivery schedule, so that Global Marine Group could immediately begin operating the system offshore on its first project.

By leveraging our strong ploughing expertise and working very closely with our supply chain, we were able to deliver the completed system within an industry leading 20-week lead-time, ready to enter work offshore.

An award-winning success.

Following the plough’s successful delivery, Global Marine Group successfully completed its first inter-array installation contract for a major Swedish developer.

Six months after project completion, we were delighted to be awarded the Marine Science & Technology Award for this plough, together with Global Marine Group, at the annual EEEGR awards.

The award was given to recognise the system’s success in meeting market demand to improve the efficiency of subsea cable installation, while minimising risk.

“Our new plough delivers an earlier return on investment for our developer clients. Through intelligent engineering alongside the Osbit team, we’ve created a versatile solution which integrates cable route preparation, cable laying and trenching, an industry first.”